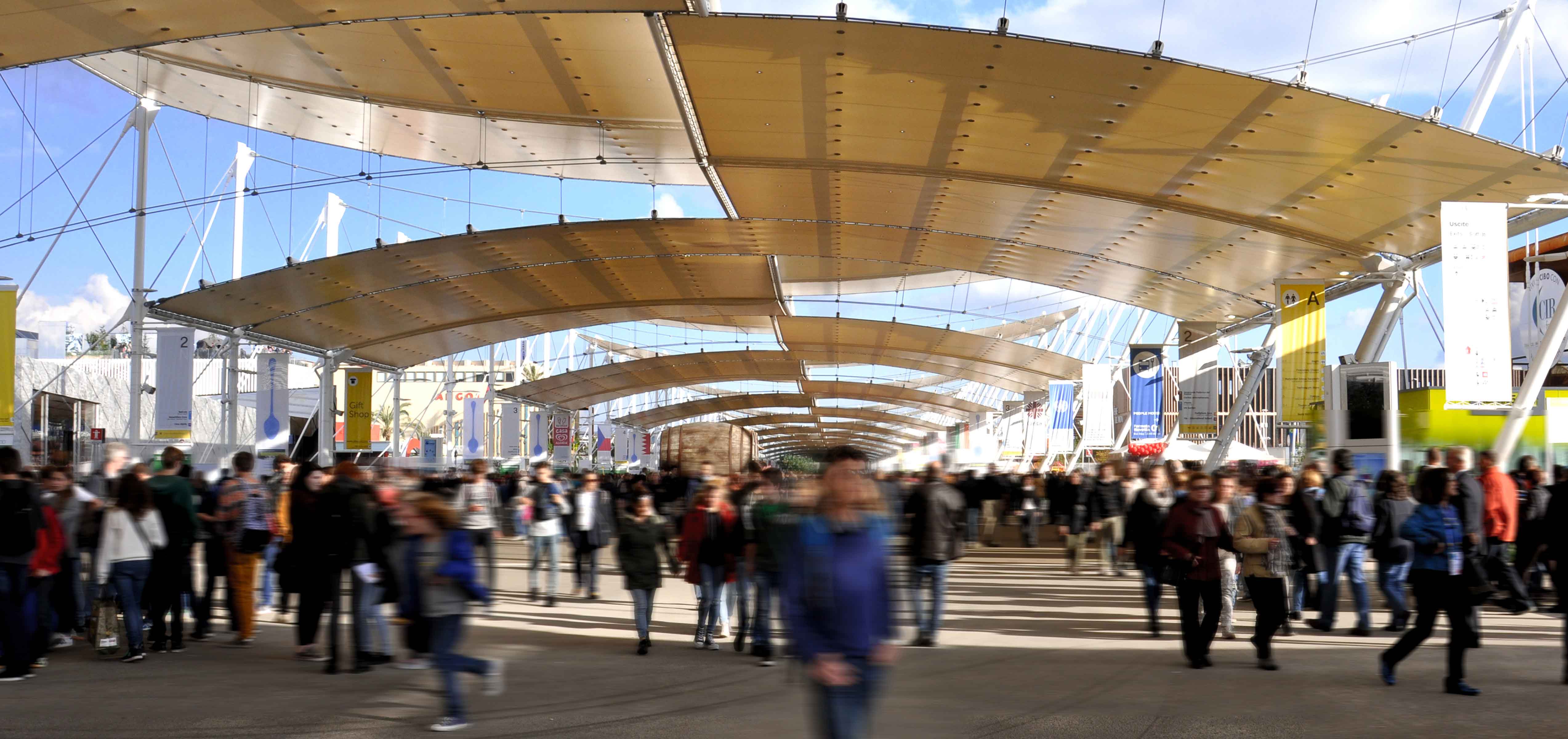

JAMARAT WALKWAY

Makkah | Saudi Arabia

YEAR

2009

STATUS

Completed

TYPE

Pedestrian Bridge

SERVICE

Special Structures | Tensile Structures | Bridges & Viaducts

FINAL CLIENT

Riyadh Municipality

CLIENT

Ali Tamimi Sons Co.

ARCHITECT

Dar Al-Handasah (Shair and Partners)

ENGINEER

Maffeis Engineering SpA

MATERIALS

Steel | Cables | Concrete | PTFE

SPAN

950 m

Dar Group was commissioned to provide design and construction supervision of a new, multi-level bridge structure that accommodates and eases the flow of 3 million worshippers during a single daylight period. The resulting Jamarat Bridge is a superior structure formed of four platform levels.

The deck floor is made of parallel box girder frames at 9 m spacing, while the deck girders are built with glued, match cast, precast concrete segments, using the free cantilever construction technique. The prestressing of the girders was made possible by internally bonded prestressing cables. Top slab prestressing tendons are anchored in the webs at the face of each segment from one side and at the face of the back columns from the other. Bottom slab cables (continuity prestressing) are anchored in bottom slab blisters.

Adjacent deck frame segments are stitched with 50 cm wide in-situ concrete and transversally stressed at cross diaphragm locations (at 12 m spacing) to form an orthotropic floor system and provide a high level of redundancy and load shedding effect. The piers and foundations were constructed using in situ reinforced concrete, except for the outer columns which were prestressed to cater for the large tension forces.

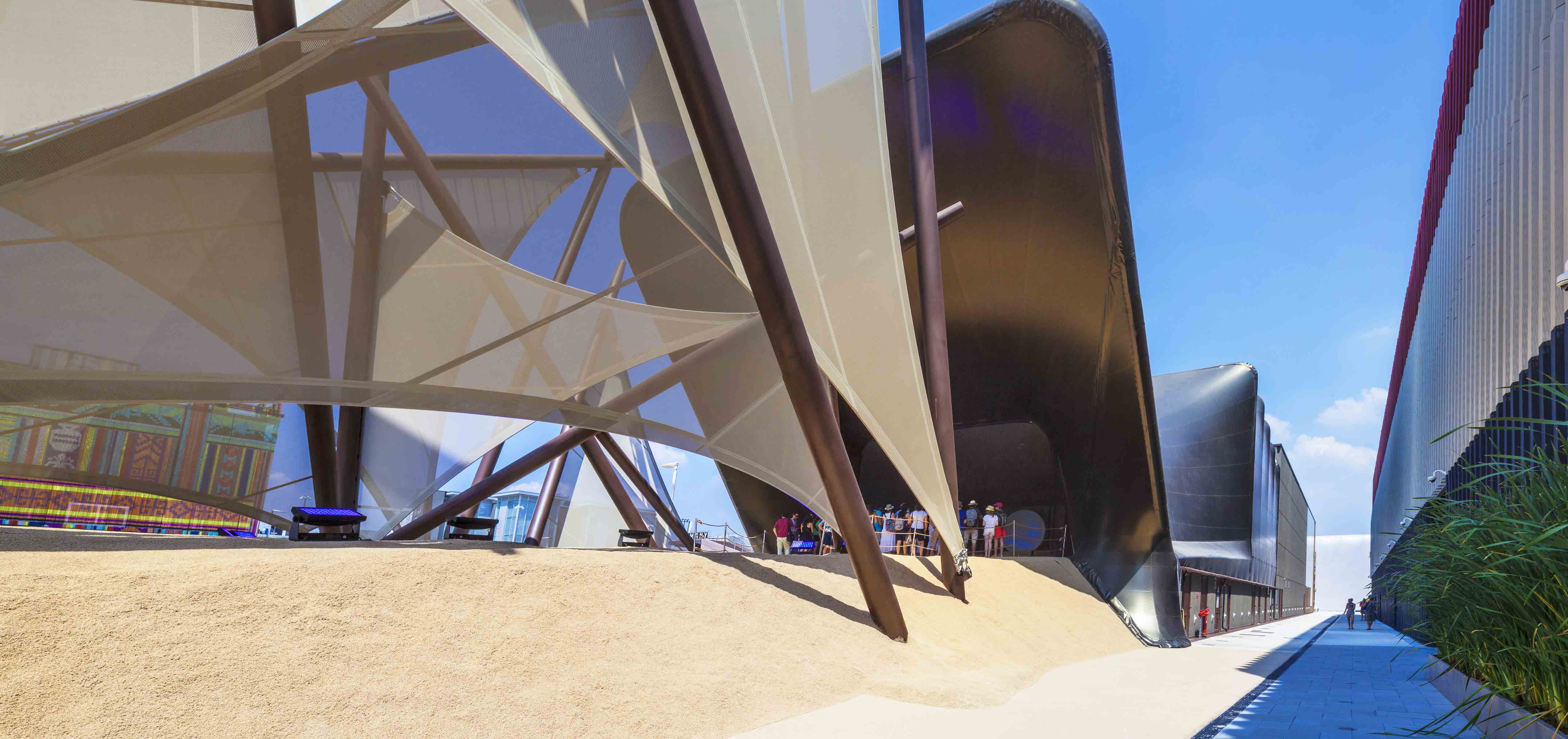

Maffeis Engineering also was commissioned for four large fabric coverings with the design of the steel, of the cables and the study of the behaviour of the mega structure in certain weather conditions.